QUALITY CONTROL

Quality Control is part of the Quality Management System (ISO 9001:2015). It has the task of ensuring that the product complies with the requirements expressed by the customer by carrying out, before delivery and during the various stages of production, all the necessary checks, tests and measurements.

The inspections that quality control carries out are supported by cutting-edge instruments that allow to measure details more or less complex by detecting their dimensional and geometric characteristics.

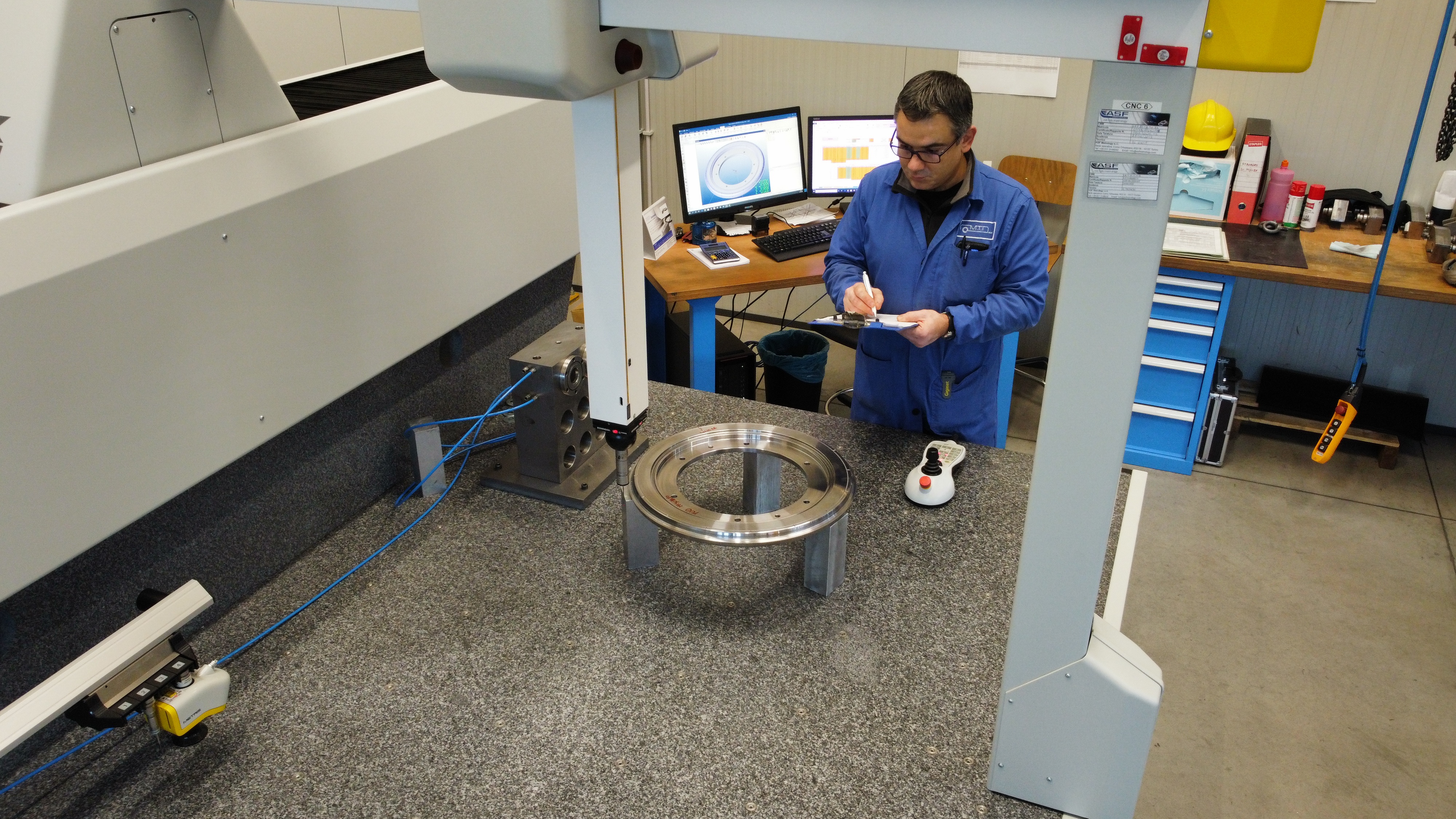

In addition to the basic metrological instrumentation (gauges, micrometers, parallel flat blocks), MTD uses a CMM (Coordinate Measuring Machine) to validate and analyze the item produced.

CMM features (Nikon model LK V 20.12.10):

- Worktop dimensions 2000x1200x1000 (X-Y-Z)

- Accuracy: 1.6 + L/400

- Automatic creation of measurement reports

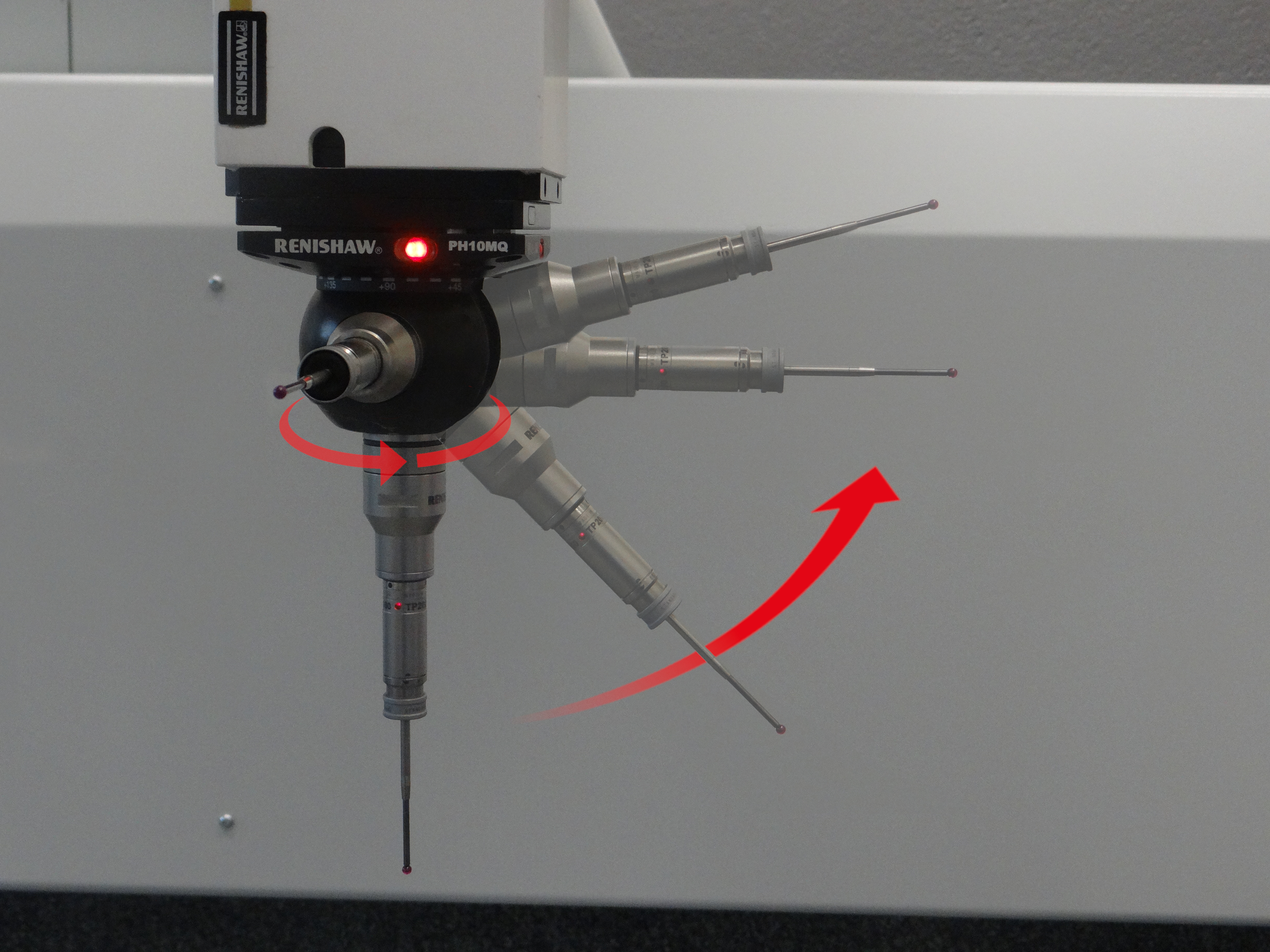

- Touch probe

- Scanning probe for profile control

- Laser scanning for surface and volume analysis

Through the use of the Laser Scan it is possible to recreate the solid through a point cloud in order to carry out a 3D analysis of the component by comparison with the mathematics used for the realization of the piece.

To ensure the full efficiency of the machine, the parent company annually carries out checks, maintenance and calibrations according to current UNI regulations, certifying the outcome through the ISO 10360-2: 2010 certificate.

MTD has a metrology room isolated from the workshop and kept at a constant temperature 365 days a year.

Contact Us

For any kind of information, or request for a quote, do not hesitate to contact us.