3D RAPID PROTOTYPING

In 2019 we decided to invest in additive manufacturing technology.

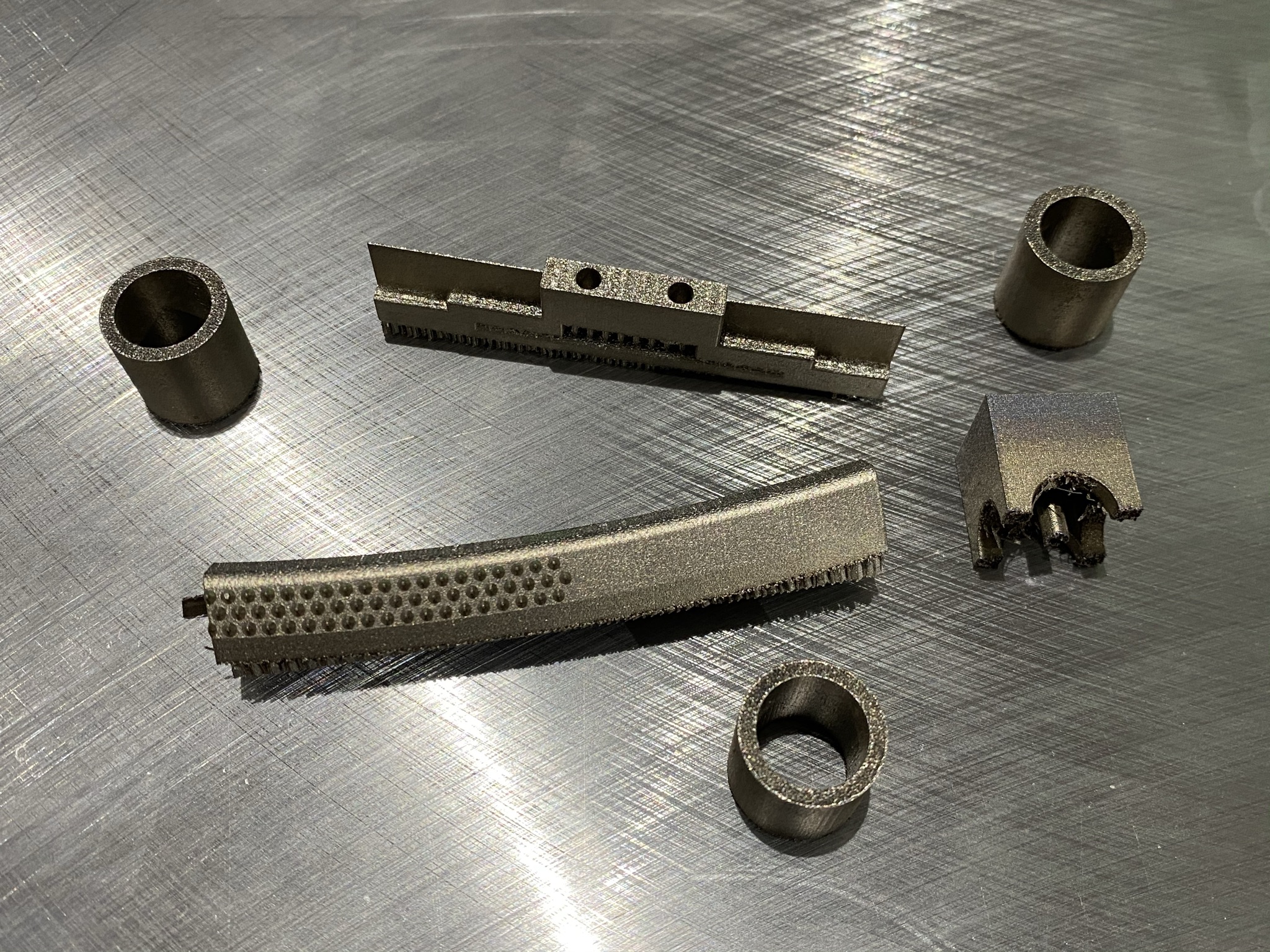

After 2 years of using this technology to make very small components with very elaborate geometries we have acquired the necessary know-how to make the most of this technology.

In fact, for some time we have been able to satisfy the most varied requests of our customers who are increasingly satisfied with the samples made by our machines that allow us to create sintered mechanical components in significantly reduced times, avoiding the use of conventional processing and saving material, machine set-up times and tools.

The quality of the density of the samples is such that in most cases it is possible to make micro holes inside them, continuing to guarantee the seal under pressure of liquids.

In several cases the requests we received concerned rapid prototyping of extremely experimental components that, through an initial inspection of the samples produced, it was possible to understand and solve structural problems that were not evident from the design via Cad.

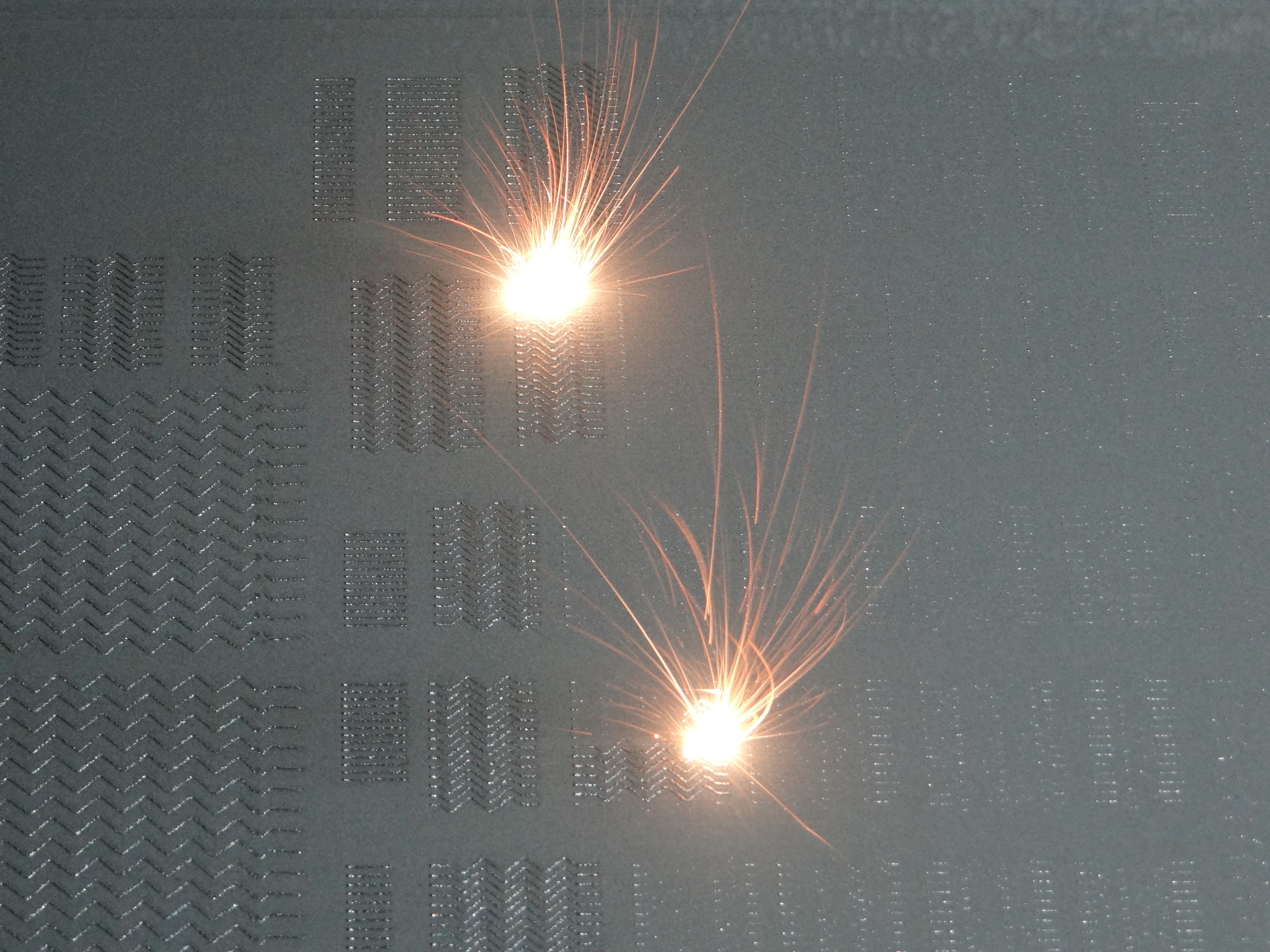

The 2 printers in our possession are managed by a proprietary software that allows us to program in detail such as passages of fluids inside the pieces, lightened fillings with honeycomb structure of massive areas, ad hoc supports to support vaults of inclined holes and many other precautions for all the different printing needs.

The materials managed by our machines are as follows:

- CL 31 AL Aluminum alloy (AlSi10Mg)

- Cl 30 AL Aluminum alloy (AlSi12)

- CL 41 TI ELI Titanium alloy (TiAI6V4)

- CL 42TI pure commercial titanium (grade2)

- CL 20 stainless steel 1.4404, AiSi 316L

- CL 50WS maragin steel for hot working 1.2709 powder for the production of inserts for plastic molding for die-casting tensile strength 1.100-1.400 N/mm2 hardness about 40HRC after hardening 1.600-1.900 N/mm2 hardness up to 52-54 HRC

- CL 91RW hot working steel

- CL 92PH stainless steel precipitation hardenable

- CL 100NB Nickel Based Alloy / Inconel 71

- CL 101NB nickel alloy/ Inconel 625 Remanium star

- CL, CoCr alloy (dental) Rematitan CL titanium alloy (dental)

- Rematitan CL titanium alloy (dental)

Our technicians will be at your disposal for any clarification and any feasibility tests.

Contact Us

For any kind of information, or request for a quote, do not hesitate to contact us.