CMM NIKON LK

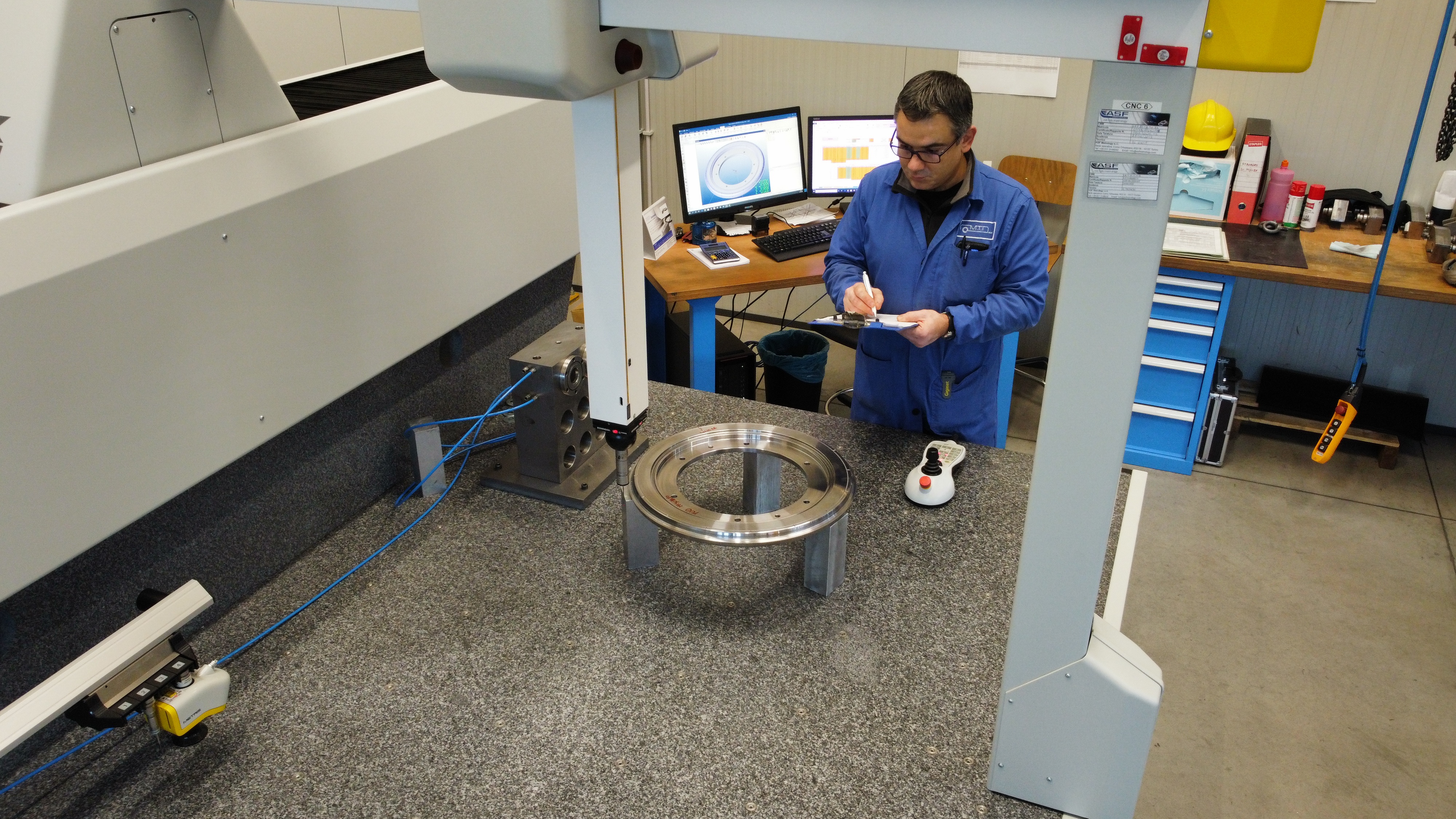

Other than basic metrology tools (calipers, micrometers, parallel flat blocks etc.), MTD uses CMM (Coordinate Measuring Machine) to validate and analyze each kind of item produced. This machine is isolated from the rest of the workshop and is installed in dedicated area, kept at constant temperature 365 days a year.

Features (model LK V 20.12.10):

- Workspace dimension: 2000x1200x1000 (X-Y-Z)

- Accuracy: 1.6 + L/400

- Automatic creation of measuring report

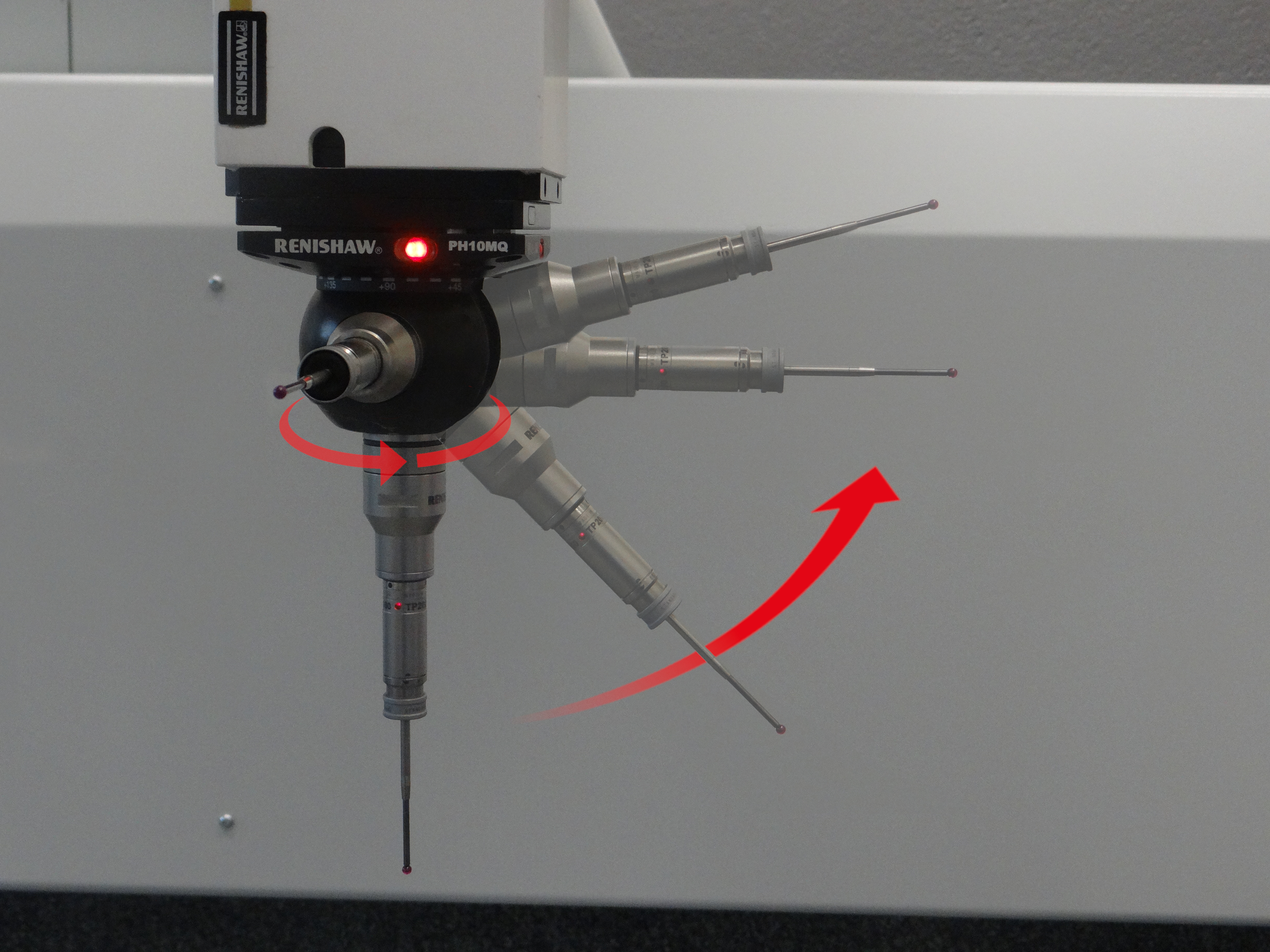

- Tactile probe

- Scanning probe for profile check

- Laser scan for surface and volume analysis

Through the use of the Laser Scan it is possible to recreate the solid through a point cloud in order to carry out a 3D analysis of the component by comparison with the mathematics used for the realization of the piece.

To ensure the full efficiency of the machine, the parent company annually carries out checks, maintenance and calibrations according to current UNI regulations, certifying the outcome through the ISO 10360-2: 2010 certificate.

Contact Us

For any kind of information, or request for a quote, do not hesitate to contact us.

Address:

Via Nicaragua, 8/A 00071 Pomezia, RomaPhone Number:

Email:

Your message has been sent. Thank you!